Plant Source: Tagetes erecta (Marigold Flowers)

CAS No.: 127-40-2

Molecular Formula: C40H56O2

Appearance: Red-orange CWS, CWD, Beadlets

Shelf life: 24 months

Although lutein is frequently added to eye care products, its bioavailability makes regular granules increasingly scarce. Therefore, nanoparticles and preparation techniques that mimic cell membrane structures, such as nanoliposome preparations, have been used to create microencapsulated products that can increase bioavailability, decrease dosage, lower drug toxicity, and defends lutein against gastrointestinal enzyme deterioration.

1. Due to the unstable physical and chemical characteristics of lutein, processes such as isomerization and oxidation will unavoidably take place during the preparation, storage, and processing stages.

2. Ordinary extract powder has issues including poor water solubility and unstable characteristics during the end-product production process.

3. Traditional preparations’ effects on the gastrointestinal system and bioavailability are poor because of the excessively large particle size.

1. 100% natural source. We strictly monitor pesticide residues on our own 1,000-acre marigold flower planting base.

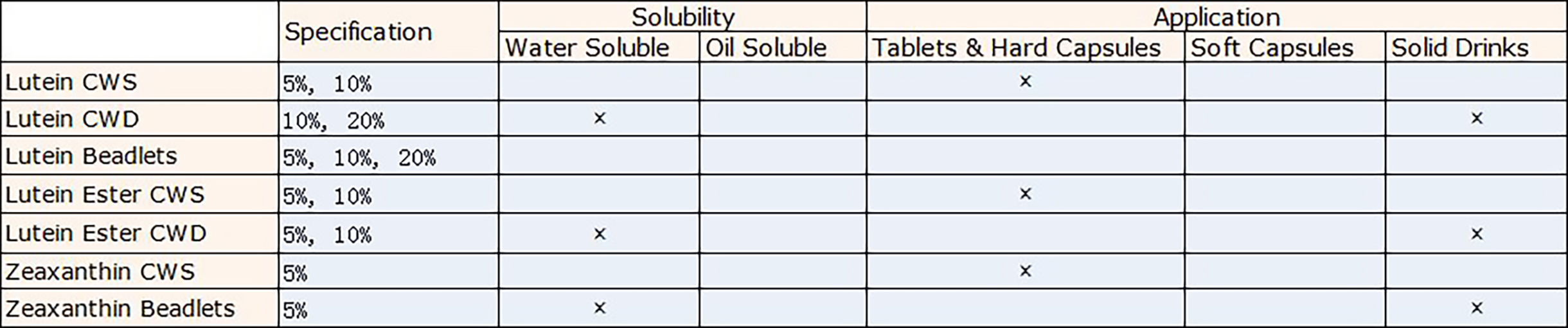

2. Meet the requirements of different dose formulations. various product forms, including powders, oil suspensions, CWS, CWD, and beads.

3. Stringent quality assurance. In order to guarantee product quality, it also complies with enterprise standards, global standards, and test results from independent laboratories.

4. Personalized service and technical support in one place. To create a long-term partnership of mutual benefit and win-win, we offer one-stop tailored services based on the demands of various customers.

5. Thorough certification. Conforms to ISO 9001, ISO 22000, and HACCP, and is KOSHER and HALAL certified.

1. What’s the difference between CWS and Beadlets?

The drying process used by CWS uses a high temperature of about 170 °C, which makes it simple to isomerize or degrade the useful compounds while reducing drying time, energy consumption, and cost.

Around 50°C is the low temperature at which beads are dried. The beneficial compounds are difficult to break down or isomerize at this temperature, but drying takes a long time, uses a lot of energy, and is expensive.

2. What’s the difference between CWD and Beadlets?

The procedure is distinct. The purpose of CWD is to rapidly fracture the lutein crystals such that, under intense pressure, the particle size is reduced to the nanoscale range. This step is not present in Beadlets.

3. What are the benefits of microencapsulated products compared to regular powders?

Microcapsules are the exterior capsule structure that encloses the target substance in microencapsulated products. Before reaching the small intestine to be absorbed by the body, gastric acid first dissolves the outer capsule structure. This is done without harming the inside active substances. The final absorption of the human body will be better than that of the microencapsulation since the general powder lacks the protection of the microcapsule structure and will partially disintegrate in the stomach.